Suction Dredger for the sanitation of waters

Pricip

The mud water mixture is promoted with a hydraulically operated dipping device, which is provided with a milling and sucction head. By a special pump the sludge is supplied by means of a buoyant transportation line to a dressing plant. This separates first the rough properties (branches, stones, bottles, etc.) of the sand and the fine sediments. The mud arrives over further line at the thickener and from there into the mud drainage facility

Process

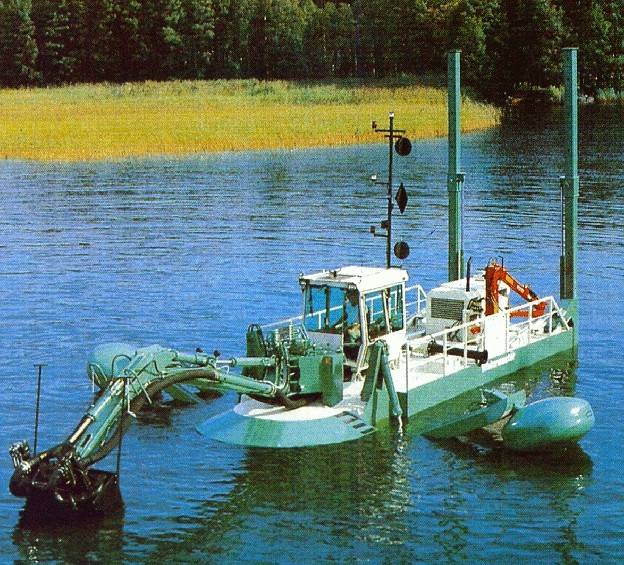

The milling and suction head is mounted on a suction dredger. (See picture).

By several passes of a cutting-, sucking- and flushing-process over the ground of the water the sludge layer is loosen and then sucked-up. The advantage is, that the native ground of the water the grown sediment is not damaged. This becomes possible through a hydralic with a fine tunig and adjustment facility.

This milling and loosening of sludge from the ground does not cause any turbidity because this sucking mill head removes the loosend sludge immediately. The milling- sucktion- process can be monitored and is displayed by an onboard computer system. This requires first a advanced seamless dual frequency scanning of the ground topography and the thickness of the available sludge layer using a special type of boat based sonar scanning device.

The computer display shows to the dredger driver the exact position of the sucking mill head whether he still removes the mud layer, approaches the grown sediments or clears away from the sediment already.

The swimming sucktion dredger is equiped with a hydralic moving and positioning facility and it can be manovered and positioned very exactly, which makes a precise methodical milling- and sucktion procedure possible. A differential GPS helps to reach and maintain very exact positions.

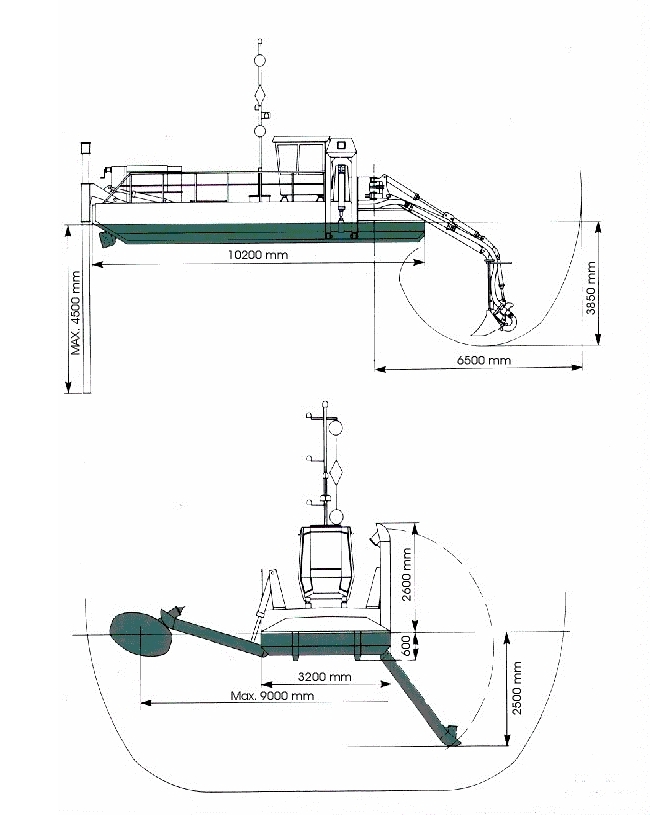

Sucktion dredger reach and dimensions

Advantages of the process

In comparsion to conventioneal methods of mud derdging with a spone, or a "Draglinen" or a other sucktion procedure straigth to a sludge pond, our procedure has the following advantages.

- The water level does not have to be lowered around the sediments to remove.

- Larger depths can be achieved by extensions.

- An off-fish is unnecessary, an impairment of the water fauna does not take place not.

- The suction procedure within the range of the milling head prevents a turbidity.

- Milling and sucking are very efficient,

- because the excavator arm movements for emptying the spawn there-falls,

- and therefore a very evenly lead milling off procedure can take place.

- The procedure permits an erosion within difficult accessible places.

- Owing to the sonar measurements, priorities can be set in the planning for the first time.

- Owing to the underwater topography maps one does not dredge any longer in clouding.

- Ponds for the mud are no longer required as these mud goes drained into truck containers.

- Providing fenzes with gates to these dangerous ponds are thus omitted.

- Approach road ways, so-called building runways to ponds are omitted thus.

- The mass volumes too dispose is substantially reduced .

- Costs for transport and dump are reduced.

- The milled off property, sand, drained mud and waste can be openly removed.

- without contamination of the roads, and

- without special trucks

- Mud and sand fractions are free from waste, every now and then dangerous kind. This is particularly important if the course of material has to be recycled.

- Dump locations can be selected therefore in direct proximity to the building site and are safely accessible thereafter.

- The Sand-fraktion can be used for building projects .

- Occasionally also archaeological finds are promoted to day.

- No emmissionen of bad smell develops.

- The noise emmissions are insignificant.

- The generator sets are sound-isolated, developed after newest state of the art.