Sludge treatment

The mud water mixture is led across a filtering device where rough particles more largely than 4mm and rubish are separated.

the mixture is then supplied to a separation cyclone where sand portions with a grain size larger then 40 Microns are separated

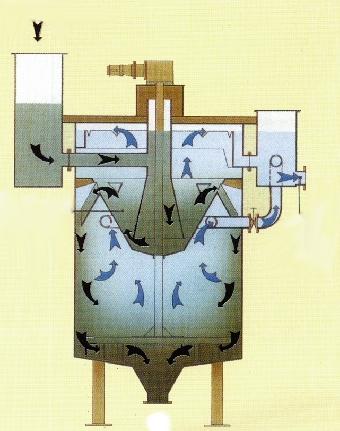

and last the medium arrives at the thickener where under addition of flocculation means the mud is ausgeflockt and thickened.

From the thickener the sludge is supplied to the mobile de-hydration system. The mud is interspersed again with flocculationa means and reaches over a snail or screen press the drained condition. In unassailable form it is supplied to a hollow or a container for the further thermale utilization.

Environmental protection

The use of Polyelektrolyte (Flockungsmittel) has no negativ impact on flora and fauna, they consist of organic substances and once arranged, decompose within short time again. Products are used, which are usually used in water purification plants and during the drinking water processing.

Equally biologically degradable oils are used in hydraulics.

The odor emissions are insignificant.

The noise emissions are so small that no disturbance of the peace is caused.

Water quality

The water led back into its natural environment can be and is examined sequentially for the following parameters.

- Temperature

- pH-value

- Turbidity

- Electrical conductivity

- Oxygen content

Further parameters on request, in particular with expected or proven pollution impact. All measured values are transferred for building daily reports or can be called-up and seen on-line by the responsible persons and authorities, authorized through secure web pages.